The construction industry is undergoing a significant evolution due to the integration of advanced technologies that are revolutionising traditional surveying and data collection processes. Innovations such as terrestrial and aerial LiDAR scanners, high-precision GPS systems, and robotic layout devices are redefining industry standards. These tools not only enhance efficiency by accelerating processes but also enable substantial cost reductions and unparalleled accuracy in projects.

Architects and engineers use data from terrestrial and aerial LiDAR scans to create detailed terrain and structural models, optimising designs and reducing margins of error.

Civil engineers rely on LiDAR scanning and GPS to generate accurate topographic surveys essential for constructing roads, bridges, and complex infrastructure projects.

Project managers employ these technologies to track construction progress against initial designs, ensuring adherence to schedules and budgets.

Contractors and surveyors use robotic total stations to execute layouts with millimetric accuracy, speeding up critical processes and ensuring quality in project execution.

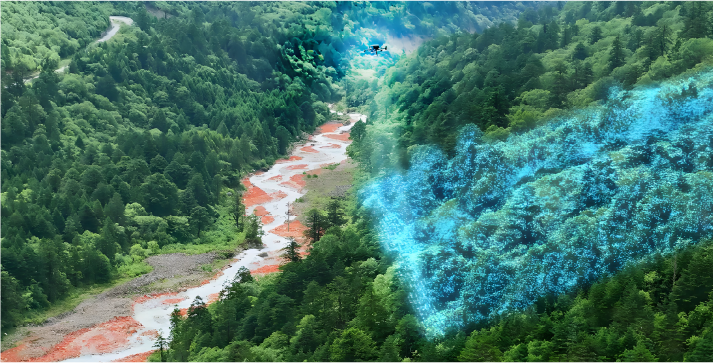

Aerial LiDAR scanning is vital for supervising extensive areas in urbanisation, mining, or energy projects, providing comprehensive data in less time and with greater safety.

Platforms integrating these technologies facilitate collaboration among various professionals involved in a project, ensuring more efficient and coordinated execution.

LiDAR, GPS, and robotic total stations deliver millimetric accuracy, crucial for detailed designs and project execution aligned with objectives.

Automation and rapid data collection and processing enable critical tasks to be completed more quickly, optimising workflows.

The technologies provide up-to-date, verifiable information, improving planning capabilities and responsiveness to unforeseen events.

LiDAR scanning, particularly in hard-to-access areas, minimises personnel exposure to hazardous conditions, increasing site safety.

Centralised data on digital platforms promotes seamless communication and better coordination among technical teams and project managers.

The precision and traceability of data make it easier to adhere to technical, environmental, and legal standards, ensuring quality and reliability at every project stage.

Topographic technology tools have become essential for the future of construction, significantly optimising project execution. The combination of LiDAR, robotic layout, and GPS not only enhances precision and efficiency but also reduces operational costs by minimising errors and delays. Moreover, process automation increases safety by reducing worker exposure to potential risks.

The construction industry is undergoing a significant evolution due to the integration of advanced technologies that are revolutionising traditional surveying and data collection processes. Innovations such as terrestrial and aerial LiDAR scanners, high-precision GPS systems, and robotic layout devices are redefining industry standards. These tools not only enhance efficiency by accelerating processes but also enable substantial cost reductions and unparalleled accuracy in projects.

Architects and engineers use data from terrestrial and aerial LiDAR scans to create detailed terrain and structural models, optimising designs and reducing margins of error.

Civil engineers rely on LiDAR scanning and GPS to generate accurate topographic surveys essential for constructing roads, bridges, and complex infrastructure projects.

Project managers employ these technologies to track construction progress against initial designs, ensuring adherence to schedules and budgets.

Contractors and surveyors use robotic total stations to execute layouts with millimetric accuracy, speeding up critical processes and ensuring quality in project execution.

Aerial LiDAR scanning is vital for supervising extensive areas in urbanisation, mining, or energy projects, providing comprehensive data in less time and with greater safety.

Platforms integrating these technologies facilitate collaboration among various professionals involved in a project, ensuring more efficient and coordinated execution.

LiDAR, GPS, and robotic total stations deliver millimetric accuracy, crucial for detailed designs and project execution aligned with objectives.

Automation and rapid data collection and processing enable critical tasks to be completed more quickly, optimising workflows.

The technologies provide up-to-date, verifiable information, improving planning capabilities and responsiveness to unforeseen events.

LiDAR scanning, particularly in hard-to-access areas, minimises personnel exposure to hazardous conditions, increasing site safety.

Centralised data on digital platforms promotes seamless communication and better coordination among technical teams and project managers.

The precision and traceability of data make it easier to adhere to technical, environmental, and legal standards, ensuring quality and reliability at every project stage.

Topographic technology tools have become essential for the future of construction, significantly optimising project execution. The combination of LiDAR, robotic layout, and GPS not only enhances precision and efficiency but also reduces operational costs by minimising errors and delays. Moreover, process automation increases safety by reducing worker exposure to potential risks.